OEM/ODM China Hdpe Pipe Fusion Welding Machine - SHD630 Hydraulic Butt Fusion Welding Machine – Lechuang

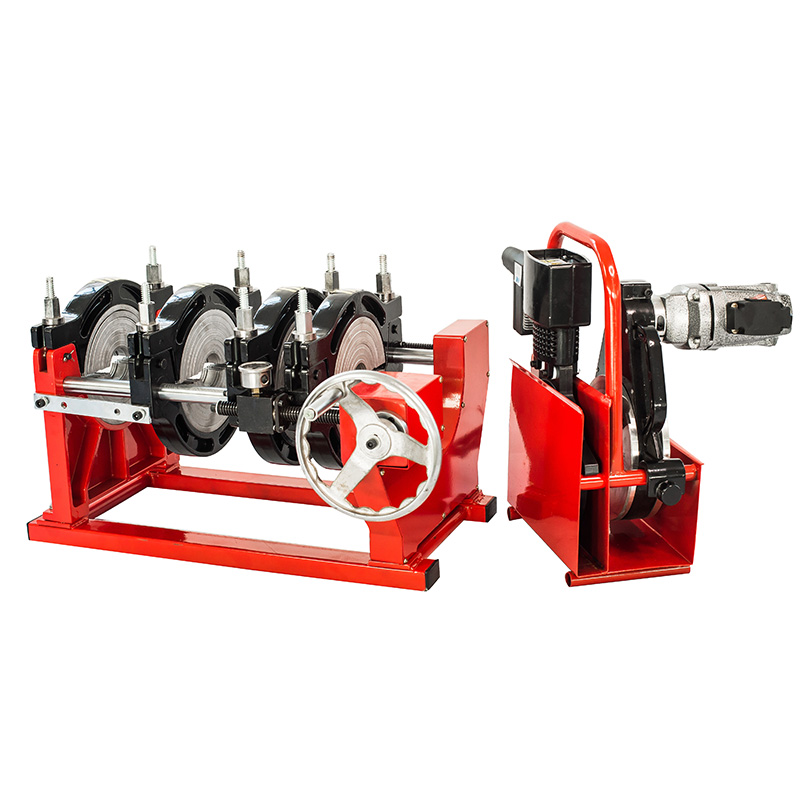

OEM/ODM China Hdpe Pipe Fusion Welding Machine - SHD630 Hydraulic Butt Fusion Welding Machine – Lechuang Detail:

PE Pipe Welding Machine Other Names

But Fusion Welding Machine, Hotmelt Welding Machine, Hydraulic butt fusion welding machine. Hydraulic butt welding machine, HDPE butt fusion machine. Welding machine. Butt fusion Equipment. HDPE Pipe Joint Welding Machine, Pipe Jointing Welding Machine, Poly welding machine. Plastic pipe fusion welding machine.

Features

1. Suitable for butt welding of plastic pipes and fittings made of HDPE, PPR and PVDF in a ditch in worksite or workshop.

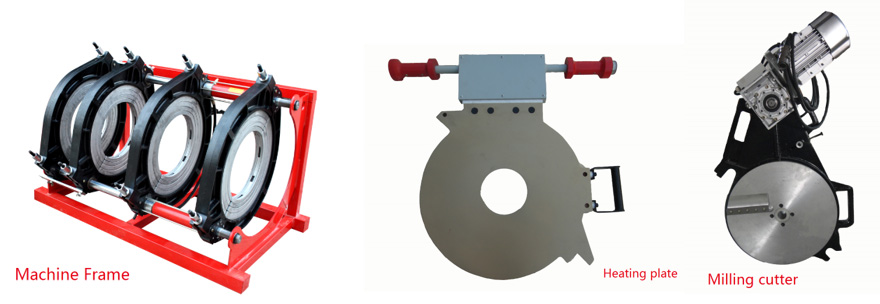

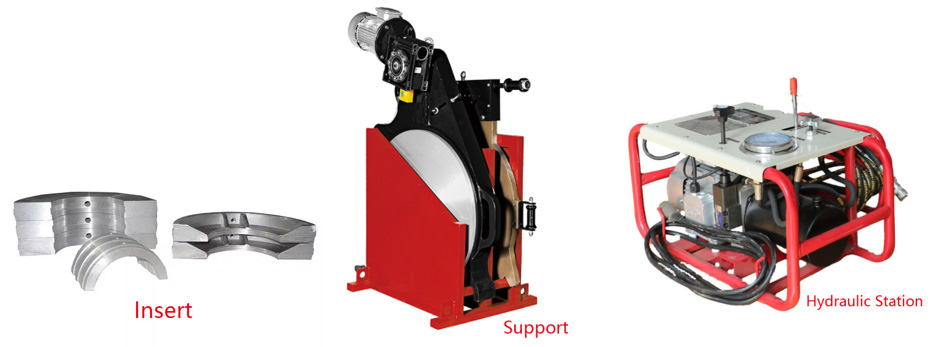

2. Consists of basic frame, hydraulic unit, planing tool, heating plate, support for planing tool & heating plate, and optional parts.

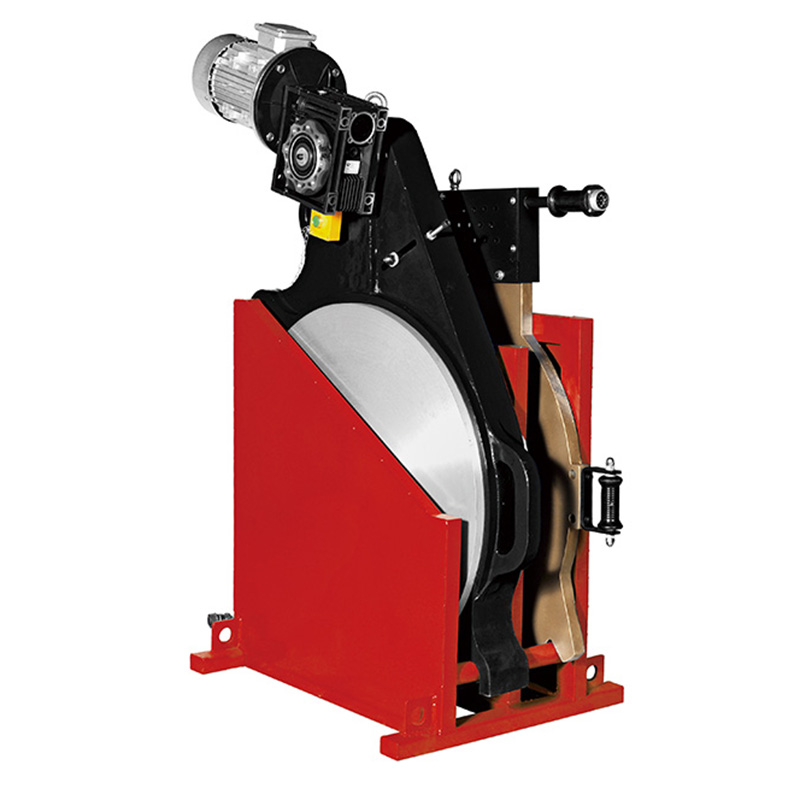

3. Removable PTFE coated heating plate with high accurate temperature control system;

4. Electrical planing tool.

5. Be made of lightweight and high strength material; simple structure, small and delicate, user friendly.

6. Low starting pressure ensures reliable welding quality of small pipes.

7. Changeable welding position enables to weld various fittings more easily.

8. Hydraulic pump with controls, and quick release hoses. Includes countdown timers for heating and cooling phases.

9. High accurate and shockproof pressure meter indicates clearer readings.

10. Separate two-channel timer records time in soaking and cooling phases.

Specification

|

Model |

SHD630 |

|

Welding range(mm) |

315mm-355mm- 400mm-450mm-500mm-560mm-630mm |

|

Heating plate temperature |

270°C |

|

Heating plate surface |

<±7°C |

|

Pressure adjustment range |

0-6.3MPa |

|

Cross-sectional area of the cylinder |

2306mm² |

|

Working Voltage |

380V,50Hz |

|

Heating plate power |

9.2KW |

|

Cutter power |

1.5KW |

|

Hydraulic station power |

1.5KW |

|

Total Power |

12.2KW |

|

N.G. |

550KG |

|

M.G. |

660KG |

|

Volume |

3.65m³ |

Service

1. 18 month warranty, all life maintenance.

2. In warranty time, if non-artificial reason damaged can take old change new for free. Out of warranty time, we can Offer maintenance service.

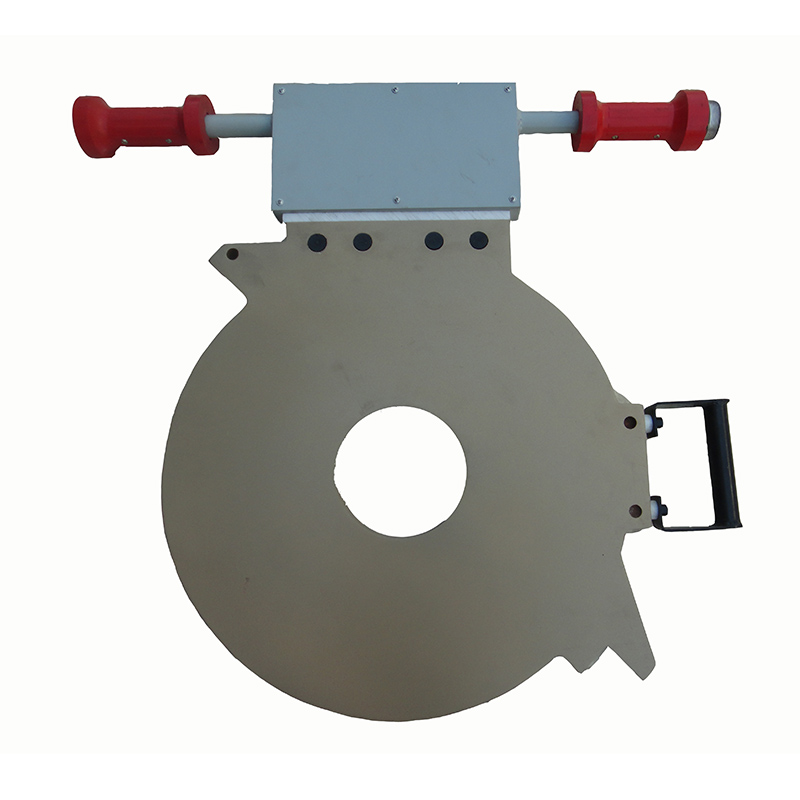

Machine Detail Photos

Machine Working

Packing and Delivery

Product detail pictures:

Related Product Guide:

Our company since its inception, always regards product quality as enterprise life, continuously improve production technology, improve product quality and continuously strengthen enterprise total quality management, in strict accordance with the national standard ISO 9001:2000 for OEM/ODM China Hdpe Pipe Fusion Welding Machine - SHD630 Hydraulic Butt Fusion Welding Machine – Lechuang , The product will supply to all over the world, such as: Seattle, Tunisia, Mozambique, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.